Machining

Maranta Srl lathing deals with precision mechanical machining to manufacture small mechanical parts to the customer's specifications for many different types of uses.

We machine brass, stainless steel, alloyed steel, aluminium and plastic for the manufacture of:

We machine brass, stainless steel, alloyed steel, aluminium and plastic for the manufacture of:

- valves and junctions,

- screws and pins,

- electronic and safety components,

- pistons and components for motors,

- sensors and rods,

- many other items made to order for the customer.

- mobile Citizen CNC sliding-head lathes,

- Gildemeister CNC sliding-head lathes,

- Biglia CNC fixed lathes,

- washing system,

- workshop equipment for finishing of parts.

- lathing,

- milling,

- drilling and microdrilling,

- deburring,

- manual and mechanical assembly,

- washing of parts,

- corrections,

- heat treatments,

- superficial treatments.

Lathing and milling

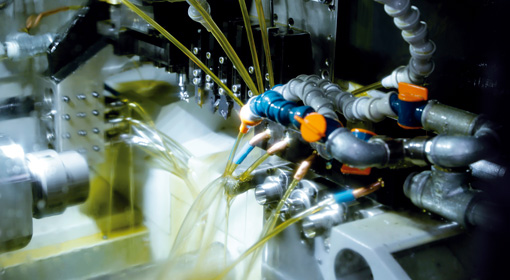

Lathing, always the core business of the company, is managed by our expert technicians with the help of a complete and efficient machine fleet.

We choose to use a specific machine based on the complexity of the part that needs to be machined: our lathes have from 2 to 10 shafts that allow for machining items of various sizes and to perform lathing and milling machining at the same time on the part, without needing to remachine.

Precision microdrilling

We perform the highest precision drilling and microdrilling starting from 0.1 mm in diameter.

Microdrilling is often used in the taps and valve sectors with which we have a long history.

Item washing

After manufacture we wash dirty and greasy parts to prevent the presence of residues. We perform this operation on all our items to deliver products compliant with regulations and not contaminated with polluting residues.

Deburring and visual control

After the manufacturing cycle the parts undergo a careful deburring and refining operation and, if necessary, we perform an accurate control of the part with specific optical instruments to verify the total lack of defects and imperfections.

Manual and mechanical assembly

If requested, we can also assemble one part onto another so that an item can be delivered ready for final use, without further loss of time on your end. For example:

Corrections, heat, superficial, tumbling treatments

Thanks to our collaboration with some certified companies in the sector we perform superficial heat treatments such as quenching, carbonitriding, case hardening, corrections, burnishing, phosphating, galvanising, anodizing and tumbling.

Therefore we can deliver a finished product to you that does not require further processing.

Sampling and prototyping

Upon customer request, before starting production, we perform sampling and prototyping of small parts of any shape for dimensions that can vary from 3 to 42 mm. Our technical office studies the best project to ensure the lowest cost and functionality of the item requested.

Lathing, always the core business of the company, is managed by our expert technicians with the help of a complete and efficient machine fleet.

We choose to use a specific machine based on the complexity of the part that needs to be machined: our lathes have from 2 to 10 shafts that allow for machining items of various sizes and to perform lathing and milling machining at the same time on the part, without needing to remachine.

Precision microdrilling

We perform the highest precision drilling and microdrilling starting from 0.1 mm in diameter.

Microdrilling is often used in the taps and valve sectors with which we have a long history.

Item washing

After manufacture we wash dirty and greasy parts to prevent the presence of residues. We perform this operation on all our items to deliver products compliant with regulations and not contaminated with polluting residues.

Deburring and visual control

After the manufacturing cycle the parts undergo a careful deburring and refining operation and, if necessary, we perform an accurate control of the part with specific optical instruments to verify the total lack of defects and imperfections.

Manual and mechanical assembly

If requested, we can also assemble one part onto another so that an item can be delivered ready for final use, without further loss of time on your end. For example:

- O-Rings mounted onto gas seal valves,

- toilet seat hinges,

- mechanical components for furniture.

Corrections, heat, superficial, tumbling treatments

Thanks to our collaboration with some certified companies in the sector we perform superficial heat treatments such as quenching, carbonitriding, case hardening, corrections, burnishing, phosphating, galvanising, anodizing and tumbling.

Therefore we can deliver a finished product to you that does not require further processing.

Sampling and prototyping

Upon customer request, before starting production, we perform sampling and prototyping of small parts of any shape for dimensions that can vary from 3 to 42 mm. Our technical office studies the best project to ensure the lowest cost and functionality of the item requested.